We’re at the start of a clean energy transition, and already facing a significant hurdle: high-performance battery technologies, particularly the ones powering electric vehicles (EVs), are still only accessible to a wealthy minority of drivers. Additionally, a limited number of EV charging stations and (relatively) limited driving ranges continue to steer most drivers toward conventional or hybrid vehicles, locking them in to another ten to twenty years of tailpipe carbon emissions and slowing the clean energy transition.

High Vehicle Range = High Vehicle Cost

EVs that can travel more than 200 miles on a single charge, enough to overcome “range anxiety,” are typically luxury models that only the wealthy can afford. The peace of mind that comes with a long-range battery pack – featured in models such as the Tesla Model 3 – comes at a minimum price of around $40,000 before subsidies and incentives, which the average American consumer just can’t afford. The disparity in other parts of the world is even starker.

Cost isn’t the only factor. Fast-charging networks (where they exist) have been built to support early adopters of EVs, who tend to live in wealthier areas. Drivers of lower-price, lower-range EVs largely depend on slower home chargers and may continue to own other conventional or hybrid vehicles for use on longer trips.

Like other clean energy technologies, accelerated consumer adoption of EVs will only come through increased confidence in the technology and reduced cost. Although we have the EV range capability (mostly) solved, prices remain an issue.

Something Is Being Done About Affordability, But…

Some automakers are changing the chemistry of their batteries to maintain range but decrease battery pack costs, which can account for 40% of the entire cost of an EV.

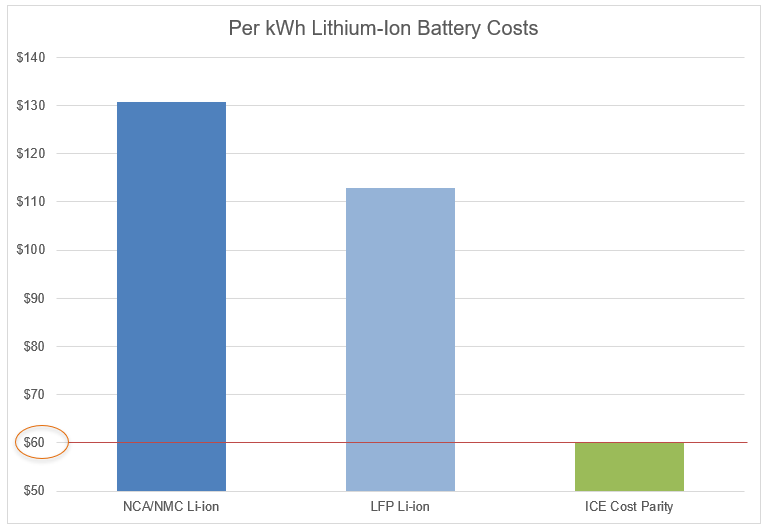

Lithium-Iron-Phosphate (LFP) batteries have become a new focal point for automakers such as Tesla, Ford, and Mercedes Benz. By using iron and phosphate in the cathode rather than overpriced and undersupplied nickel and cobalt, LFP battery packs were expected to be less expensive, but this is proving to not be the case as lithium prices rise.

However, LFP is only incrementally cheaper, and current supplies of battery-grade lithium are insufficient for demand to the point that Benchmark Mineral Intelligence recently stated “raw materials [for lithium-ion batteries] are entering the realm of impossible.” It’s clear that LFP alone isn’t going to drive down prices for EVs like automakers hoped it would.

A Bolder Solution is Still Necessary

To reach our zero-carbon future, we need to substantially bring down the cost of high-performance battery packs and keep them there. According to the U.S. DOE’s Director of the Vehicle Technologies Office (VTO) Dave Howell, EV battery costs need to fall by more than 50 percent, to $60 per kWh, in order to reach cost parity with internal combustion engines. “By getting to $60/kWh, an EV’s total cost of ownership will be 26 cents a mile. Combustion is 27 cents.”

We need to consider adopting a battery that performs like lithium ion but that can be made with readily available, low-cost materials. Leaving behind lithium, nickel, and cobalt and using materials that are cheap and easy to source will ultimately get more drivers behind the wheel of an EV.

Alsym is committed to delivering batteries with lithium-ion-like energy density at less than half the cost. Our materials aren’t as sensitive to global supply chains and scarcities because we don’t use the expensive lithium, nickel and cobalt found in lithium-ion batteries. By using materials that are plentiful, accessible, non-flammable, and non-toxic, we can ensure an economically viable path to displace internal combustion engines and increase battery availability for the global energy transition.

Want to find out more about a new generation of affordable batteries? Get in touch!