No fires, no explosions, no toxic gases

Alsym’s non-lithium battery chemistry is inherently non-flammable and non-toxic, providing a level of safety that is desperately needed but can’t be met by lithium-ion. This makes it the only high-performance option that’s truly viable for safety-sensitive, space-constrained industries, including microgrids, urban areas, residences, and data centers.

The problem with lithium-ion for BESS

This risk is especially significant when it comes to stationary storage. A single 20′ storage container can have 100x the energy capacity of an EV battery, and a single battery storage plant may have hundreds of containers co-located at a single site. At this level of capacity and concentration, a fire can quickly spread from one container to neighboring ones–to catastrophic effect.

Lithium-ion BESS fires are far worse than conventional ones. They burn at temperatures more than twice that of a conventional fire, spread in seconds, and can violently explode. They can’t be stopped until the battery cells cool down enough to end the thermal runaway process, and can’t be extinguished via conventional firefighting methods. Fires also release toxic gases such as hydrogen fluoride (HF), carbon monoxide, and other volatile organic compounds, posing serious risks to human health and the environment.

In most situations, the recommended solution is to isolate the fire, evacuate the immediate area, and then let the fire burn itself out, which can take days (or weeks). For example, a 2023 warehouse fire near San Diego, California took 17 days and 8 million gallons of water to extinguish. This strategy might be acceptable in rural or remote areas where the impact is less severe, but poses a critical danger in cities and suburbs. As more communities experience the reality of these fires, regulators and permitting authorities are becoming reluctant to deploy lithium-ion batteries.

Regulators and authorities having jurisdiction (AHJs) are now in the unenviable position of trying to balance concerns about human health and safety with concerns about the health and safety of our planet. All of this has the potential to set back or derail net-zero decarbonization goals–something the world cannot afford.

Non-toxic at every step

- Sourcing and Manufacturing | | |

Sourcing and Manufacturing

Sourcing and Manufacturing

Environmental concerns stem from the mining and processing of critical materials like lithium, cobalt, nickel, and copper. These activities damage landscapes and raise ethical issues, especially cobalt mining in the Democratic Republic of the Congo, which is linked to child labor and unsafe conditions. Processing these metals is also energy-intensive and pollutes surrounding communities.

Lithium-ion battery manufacturing introduces further risks due to hazardous chemicals like NMP, a solvent known to cause reproductive harm and long-term health issues. The production process must follow strict safety protocols to prevent fires and explosions from flammable electrolyte materials.

Additionally, lithium hexafluorophosphate (LiPF6), used in battery electrolytes, decomposes into highly toxic compounds like hydrofluoric acid when exposed to moisture, causing serious health hazards upon contact or inhalation.

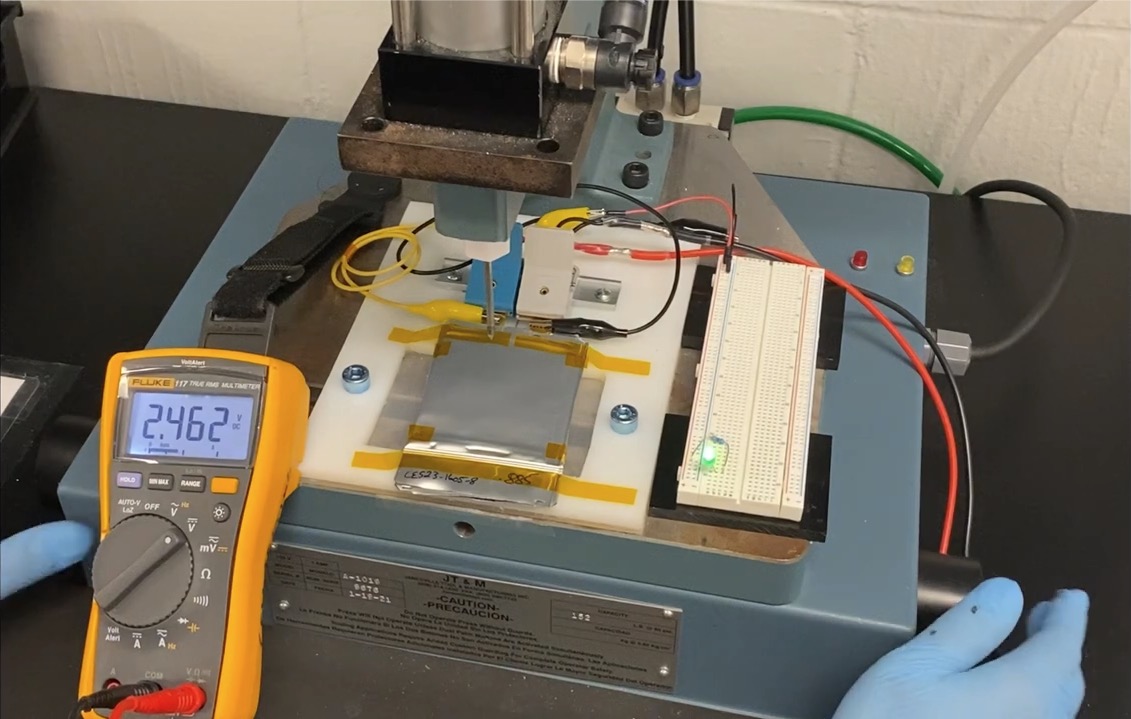

In contrast, Alsym avoids such hazards by eliminating toxic solvents like NMP and using non-flammable, non-toxic materials. Its components are responsibly sourced from domestic or free trade regions, minimizing environmental and human rights concerns.

End of Life

End of Life

At end-of-life, lithium-ion batteries present serious toxicity risks if not properly handled. They contain hazardous materials like cobalt, nickel, lithium salts, and organic solvents, which can leach into soil and groundwater when dumped in landfills, creating long-term environmental and health hazards. Recycling them also poses challenges—many methods use high heat or harsh chemicals that release toxic fumes and generate hazardous waste. Poorly regulated processes can pollute air, water, and soil, and mishandling during collection or transport can lead to fires that release harmful chemicals.

Alsym batteries are engineered to avoid these problems. Free from lithium, cobalt, and other hazardous substances, they greatly reduce the risk of contamination during disposal. Their non-toxic materials do not threaten soil or groundwater even if mismanaged, and the simplified recycling process further minimizes environmental and safety concerns compared to lithium-ion systems.

Environmental Risk

Environmental Risk

At end-of-life, lithium-ion batteries pose major toxicity risks if not properly recycled. Hazardous contents—like cobalt, nickel, lithium salts, and organic solvents—can leach into soil and groundwater from landfills, creating long-term environmental and health threats.

Recycling lithium-ion batteries often requires high heat or strong chemicals, releasing toxic fumes and producing hazardous waste. Poorly regulated processes can contaminate air and water, and mishandling during collection or dismantling can spark fires, increasing exposure to harmful substances.

In contrast, Alsym batteries contain no lithium, cobalt, or other toxic materials, reducing the risk of contamination. Their components are non-toxic even if discarded improperly, and the recycling process is simpler and safer, minimizing environmental impact.