The challenges we foresaw for the future power grid have arrived sooner than expected. Cities are electrifying at record pace. Data center infrastructure is in the megawatt-scale and projected to reach gigawatt-scale by 2028. Electric heat pumps are replacing oil and gas systems. EV sales are growing 5x faster than gas cars. At the same time, record heat waves, winter storms, and other climate extremes are undermining grid reliability. According to a report from Climate Central released last year, there have been 60 percent more heat-related power outages between 2014-2023 than in the 10 years prior. Energy infrastructure is being pulled in two directions: toward greater demand, and into tougher conditions. The combination is a major problem.

As these pressing challenges take hold, experts are increasingly pointing to battery energy storage systems (BESS) for their ability to relieve pressure on the grid. Battery storage enables greater flexibility in how and where energy is used—supporting distributed generation, deferring costly infrastructure upgrades, and improving system reliability. While lithium-ion batteries dominate the storage market, they are facing safety, supply chain, and even cost limitations that restrict widespread deployment. In contrast, sodium-ion batteries have emerged as a promising alternative, offering improved safety, high performance, and scalability to help answer the grid’s most urgent challenges.

More is Being Demanded of Batteries

In the first half of 2025 alone, utilities requested or secured more than $29 billion in rate increases, nearly doubling the same period in 2024. These hikes stem from a combination of infrastructure limitations, capacity shortfalls, and heightened demand during extreme heat. To cool rising rates, more batteries are needed in front-of and behind-the-meter to ease transmission stress and manage off-peak energy closer to where it’s consumed. If they don’t accelerate battery deployment, utilities will remain trapped in a cycle of patching deteriorating infrastructure and constructing oversized facilities—committing to multi-year projects that further drive up costs.

To compound the problem, assets supporting the grid must now operate without incident through increasingly turbulent weather patterns. Patterns that our energy system wasn’t originally planned for – drought, deep freezes, hurricanes, and heatwaves – now frequently push infrastructure to its limits. From the unusual heat in the Pacific Northwest to cold snaps in Texas, extreme weather events are a persisting trend that warrant a strategic response with respect to infrastructure.

The Status Quo is Not Enough

We know how energy storage can relieve system stress and support resiliency in the face of grid turmoil – the question is how can we get more storage connected, faster, and with fewer barriers to tap its full potential.

Lithium-ion batteries, which make up 99% of new storage installations, have blazed the trail for batteries managing energy at scale. But they also carry limitations that call into question their ability to support the grid’s new normal.

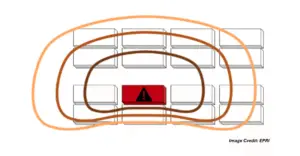

These batteries use flammable and toxic materials, raising safety concerns that slow down permitting and installation. Furthermore, lithium-ion batteries require tightly controlled environmental conditions to operate at peak performance and avoid failure; these make layers of cooling, ventilation, containment, and control a requirement at the system level —adding cost, complexity, and operational risk. But even with these safeguards in place, failures caused by weather, system defects, and heavy use still occur. Additionally, lithium-ion’s supply chain is concentrated to just a few countries, leaving grid reliability—and national resiliency—dependent on external sources.

Together, these factors limit how quickly and widely we can connect new storage to the grid, at a time when flexibility, speed, and resilience are more important than ever.

Sodium-Ion: Built to Weather the Storm

Sodium-ion batteries can offer an answer to both lithium-ion’s shortcomings and the pressures mounting on the modern grid. It’s a technology that can endure harsher conditions, be sited with minimal extra packaging, and can scale to much greater heights due to a low-risk supply chain.

Sodium-ion offers thermal stability and environmental tolerance that enables a much wider operating temperature range. Thermal robustness allows better siting and permitting flexibility, and reduces the need for extensive fire suppression, complex cooling infrastructure, or emergency response planning if things go wrong. When storage can be deployed with fewer system add-ons and less required intervention over time, resiliency goes up and total cost of ownership comes down – saving operators money while maximizing value and revenue.

It’s worth mentioning that like lithium-ion batteries, there are multiple formulations of sodium-ion, and not all offer the capabilities needed for next-gen energy storage. Some sodium-based chemistries like NFM use flammable electrolytes to offer higher energy density at the cost of safety. Others including Prussian white offer an incremental improvement in performance but can generate highly toxic hydrogen cyanide gas if subject to abuse.

Yet new formulations of sodium-ion batteries made from sodium compounds, iron, and hard carbon — such as sodium iron pyrophosphate or “NFPP” — use materials that are safe, sustainable, and widely available through salt deposits and biomass. The next-generation of tech in this category is completely eliminating the possibility of thermal runaway. While hazard-proofing has proved a challenge for lithium-ion, the story for sodium-ion is unfolding much differently.

Meeting the Moment—Safely and at Scale

Meeting the challenge at hand requires more than just an alternative chemistry—it requires a battery purpose-built for the grid’s new reality. Sodium-ion – specifically NFPP – can be designed for scale, environmental durability, safety, and sustainability. That’s the kind of storage the grid needs now, and the kind we’re working on at Alsym Energy.